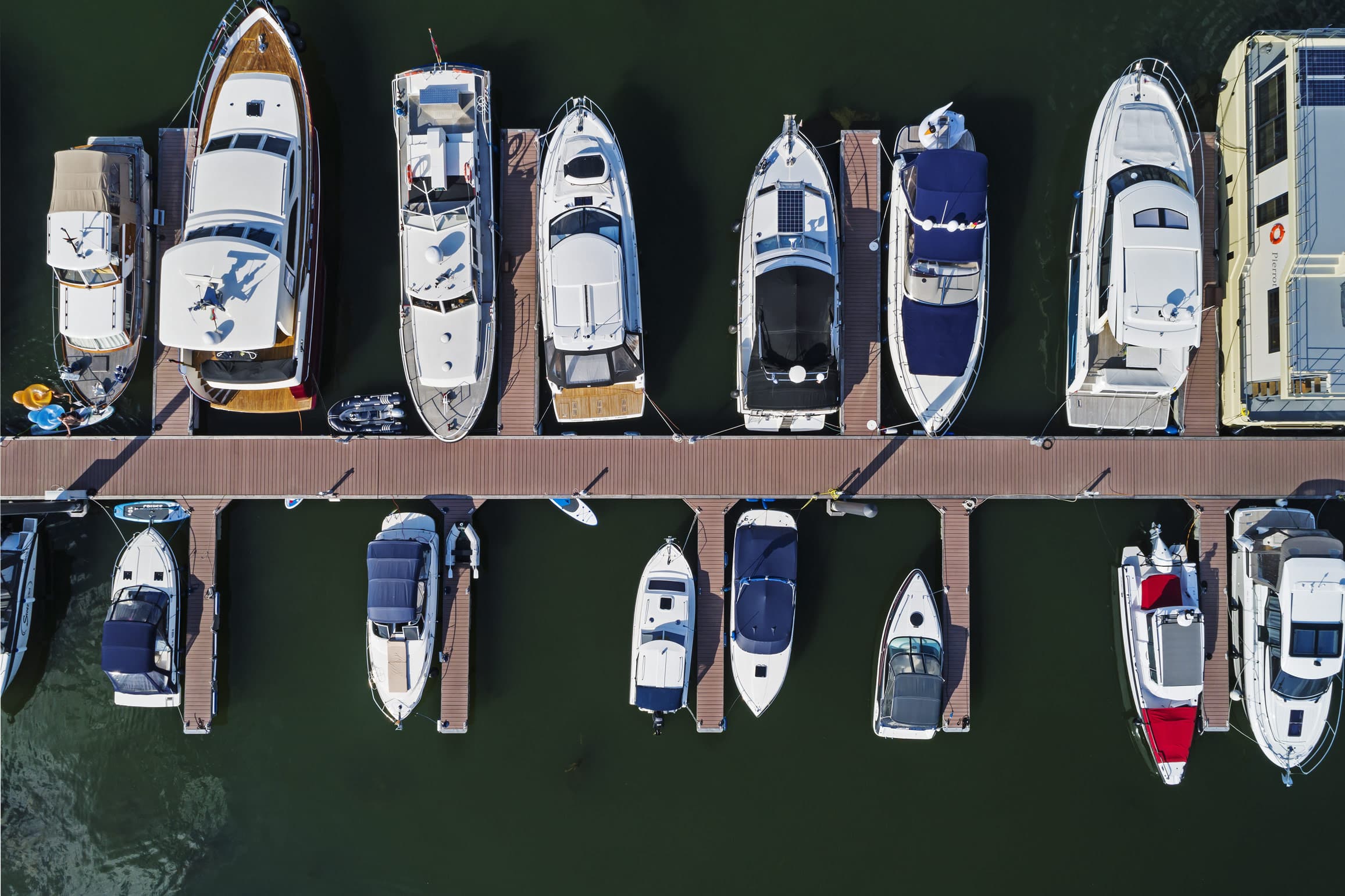

In the middle of a dynamically developing town quarter there has been a marina in the Customs Port of Mainz since 2018, with up to 140 high-quality moorings for different boat sizes. So that skippers and guests can get to their boats safely and with dry feet the operating company had two jetties built – and decided on the special supplier Inter Boat Marinas’ ‘Atlantic’ system to do so. The surface was covered on a total area of 1,600 square metres with NATURinFORM’s massive deck ‘Compact’ in brown. After around three years of intensive use the operators can now come to the conclusion: ‘The flooring is as attractive as on the first day, its slip-resistant surface structure reliably prevents accidents and is also easy to clean.’

Marina Customs Port Mainz

Patio decks

Compact in brown

Construction year

2018

Location

Marina in the Customs Port Mainz

Mainz (RP)

The quarter in the Customs Port in Mainz has grown slowly but surely closer to the docks with a lot of award-winning architecture in the last years. Since the summer of 2018 there is a new marina at which skippers can find conveniently installed moorings in the best part of the city. Everything your guests, crew, and even the Smutje enjoy is close by and within walking distance: bustling cafes, a diverse range of restaurants, grocery supplies with supermarket and health food stores – and even an art gallery right next door. The marina itself also has a lot to offer its guests – from electricity to water and wireless LAN, right at the mooring.

Recognised experts for jetty construction

To build the pier the operating company Zollhafen Mainz GmbH & Co. KG appointed Inter Boat Marinas, a Dutch company with its headquarters in Puttershoek, which is specialised in the development, production, and installation of jetties and ‘ready-to-use’ marinas since 1986. They have realised more than 1,400 projects around the world in the last years. ‘Inter Boat Marinas is not necessarily one of the less expensive suppliers, but the concept, as well as the impressive list of references, convinced us’, says Detlef Höhne, as Port Master involved in the plans. The work was performed by H&R Modultechnik with their base in Kinheim/Mosel, the German representative of the Dutch company. H&R Modultechnik specialises in facilities at and on the water. ‘We plan and develop in close cooperation with our customers to find exactly what they desire for their projects,’ says Managing Director Hans Georg Schulz. ‘Concrete jetties, floating concrete platforms, aluminium jetties, flood-safe, as well as floating sanitary and catering buildings for camp-sites and marinas are our core competence. With our ‘all in one hand formula’ we offer competent consultation, as well as support on executing work in the field of water construction work – including erecting floating and fixed jetties, impact pile driving and digging work, water and electrical supplies, as well as building fences and access checks.’

Floating jetty system with a robust surface of wood composite material

First of all, dolphins – piles to provide a fixed structure for or prevent ships from colliding, or to mark waterways – were driven into the ground of the up to four-metre-deep basin of the docks. Then the H&R Modultechnik team set up the ‘Atlantic’ system. This is a robust, floating and modular jetty system made of galvanised steel frame with main jetties and extensions, suitable for use in coastal areas or large lakes and rivers. ‘The specialty of this system in combination with concrete floats is the high tare weight,’ explains Hans Georg Schulz. An element in the dimensions 10×2.50 m is designed to carry a load of 250 kg/ m2 and weighs far more than 4 tonnes. ‘Due to this high tare weight this jetty system has a very calm position in the water,’ says Schulz. Under the main jetties concrete floats were installed, and under the additional jetties there are polyethylene floats. After the aluminium profiles were screwed on, the wood composite material decks by NATURinFORM were laid on a surface of 1,600 m2 as an optically attractive, durable, and slip-resistant upper surface.

Convincing maritime look, durability, and low maintenance

’We offer a broad range of surfaces for our jetties,’ says Hans Georg Schulz. The extensive range covers surfaces made of hard wood, waterproofed soft wood, galvanised and GRP (Glass reinforced plastic) or aluminium grates, concrete surfaces, right up to wood composite materials. ‘Our customer in Mainz decided on NATURinFORM’s ‘Compact’ after extensive consultation, especially due to the durability of the material, as well as the simple maintenance requirements.’ The latter was especially important to the operators, as the jetty is also very popular with a flock of Nile geese. ‘The large animals always leave a lot of dirt,’ says Port Master Detlef Höhne. ‘An absolute ‘must’ in the requirements catalogue was therefore that the bird droppings could be cleaned using a high-pressure cleaner without the surface being damaged. And that has worked perfectly until today,’ Höhne praises the decks’ resilience. Also, the theme sustainability played into the decision process, as during production of the decks only wooden fibres from domestic and sustainable forestry are used and no tropical wood is taken from the rain forest. Therefore ‘Compact’ with its maritime, brushed wooden deck look was clearly the winner against the competition of hard wood and GRP grates, as besides an attractive outer side the material specific characteristics such as sturdiness, low maintenance, and durability played an important part for the wood composite material ‘Made in Germany’,’ emphasises Hans Georg Schulz and adds: ‘With this material – especially from NATURinFORM’s range – we have had only positive experiences.’

Successful cooperation between Inter Boat Marinas and NATURinFORM

In the past Inter Boat Marinas worked on the supplier side mainly with Chinese and American suppliers of wood composite materials / WPC, until the company changed to NATURinFORM. The reason Erik Langerak, Director of Inter Boat Marinas, states is ‘NATURinFORM’s reliable quality.’ With the specialist from Redwitz an der Rodach the Dutch were able to realize around 12 piers, among others Hooksiel in Friesland, Papenburg and Dinslaken, to name the largest. ‘NATURinFORM convinced us of its products’ quality with its countless references, as well as the continuous tests that are performed with the material. Decisive are also the support, the quick delivery times, as well as the agreed guarantee for the material and processing costs,’ Erik Langerak sums up the reasons for changing the supplier in the past. ‘Even if we at first had to learn how to process this (new) material in practice, we definitely made the right decision here and recommend NATURinFORM’s range of products to our customers, even for use near salt water,’ says Erik Langerak, ‘here the company confirmed to us that their products are absolutely sea water resistant.’

Certified safety: Slip-resistant surfaces prevent accidents

The ’compact‘ slip-resistant surface was selected for the jetties in the Customs Port in Mainz which provides a lot of grip, regardless whether damp or wet. NATURinFORM’s massive decks have proven themselves in environments close to water, as well as on patios surrounding swimming pools. As a surface you can choose between a finely striated side or block stripes, both are brushed to provide more grip and slip resistance. With its finely striated surface it promises the highest level of slip-resistance, R12 according to DIN 51130 and Class C according to DIN 51097, as a test by the TÜV Rheinland certified. ‘Compact’ is there for predestined for surfaces in the direct proximity of water. Additionally, the finely grained decks are unfazed by spray water and guarantee a high level of surefootedness due to their technical enhancement. Unlike wood the surfaces made of wood composite material do not splinter. With a length of maximum up to 13 metres, a thickness of 21 millimetres, and by being able to be used with either side facing upwards, they can be used versatilely.

About the company: Expert for intelligent outdoor surfaces

NATURinFORM specialises in intelligent solutions for outdoor surfaces and profiles. In the factory in Upper Franconian Redwitz an der Rodach wood composite material is produced: a material that combines the optical characteristics of traditional construction timber with the durability of a technical polymer. During production wooden fibres are combined with an environmentally-friendly pure thermoplastic polymer in such a way that it covers each individual fibre like characteristics of wood. A large advantage for surfaces around damp and wet application fields: neither does the material swell and thus rot prematurely, nor does it splinter or become slippery.

Also, customers that look out for sustainable products prefer NATURinFORM. As climate protection and saving on resources are top priority for the producer. To produce the wood composite materials as certified climate-neutrally, it uses only wooden fibres from domestic and sustainable forestry (PEFC-certified wood suppliers). This means that no additional trees are felled, the wood fibres are a by-product of the wood-processing industry. All products are also 100 percent recycleable, after the decks are no longer in use they are tested and taken back by the company and re-fed into the production process.

There are environmental product declarations according to international standards available (EPDs) for all of NATURinFORM’s decks and façade profiles. All products are continuously monitored by quality controls and stress tests, to guarantee a constant perfect and first-class wood composite quality. The company provides a five-year guarantee on its products. The patio decks can be recycled 100 percent and can be returned to the plant in Bavarian Redwitz for recycling.

Download: Press release

Product information: compact